ATOM DX™ encoder series

The ATOM DX encoder series is Renishaw's smallest incremental optical encoder with digital output direct from the readhead, providing positional feedback, onboard interpolation, and filtering optics all in a miniature package.

ATOM DX builds on the market proven optical system of the ATOM™ encoder platform and integrates Renishaw's high-performance interpolation technology, reducing system size and removing the need for additional adaptors and interfaces. ATOM DX is suitable for the most space constrained applications where performance cannot be compromised.

Constructed with Renishaw's integrated set-up LED, for an intuitive and simple installation process based on the well established auto-calibration routine, ATOM DX is ready to install straight from the box. ATOM DX is compatible with both the ADTpro-100 standalone encoder diagnostic tool and the ADTi-100 diagnostic tool, both of which are compatible with the ADT View software. They provide in-depth advanced diagnostic information to aid optimisation of encoder installation and in-field fault finding to satisfy the most demanding motion control applications.

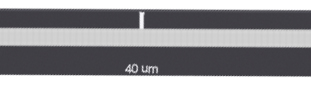

ATOM DX readheads can be used with a wide range of linear, partial arc and rotary scales to meet most application requirements, and comes in two formats: cabled and top exit variants with either 20 µm or 40 µm scale options.

Performance in a miniature head

ATOM DX fits into the smallest applications with heights as low as 7.85 mm. The top exit variant offers all the benefits and features of the cabled ATOM DX encoder, but in an even smaller package. The top exit variant is a component encoder with the cable assembly integrated separately to the readhead, making the ATOM DX top exit suitable for the smallest spaces.

Performance in speed

ATOM DX encoders offer maximum speeds up to 20 m/s and a range of high-speed interpolation options.

Performance in velocity control

ATOM DX incorporates Renishaw's latest interpolation technology, with updated signal processing algorithms to reduce Sub-Divisional Error (SDE). This helps to reduce velocity ripple and improve closed loop feedback in motion control systems.

Find your ATOM DX scale option

Linear

| Scale type | Scale name | Accuracy | Scale pitch | Coefficient of thermal expansion at 20 °C | Scale max length |

Glass spar

| ±3 µm | 20 µm/40 µm | ~8 µm/m/°C | Up to 130 mm | |

Stainless steel tape

| 20 µm: ±5 µm/m 40 µm (high accuracy): ±5 µm/m | 20 µm/40 µm | ~10.1 ±0.2 µm/m/°C | Up to 10 m (> 10 m on request) | |

Narrow stainless steel tape  | RKLF-S | 20 µm: ±5 µm/m 40 µm (high accuracy): ±5 µm/m 40 µm: ±15 µm/m | 20 µm/40 µm | Matched to substrate material when scale ends are fixed with end clamps | Up to 10 m (> 10 m on request) |

Partial arc

Scale type | Scale name | Accuracy | Scale pitch | Coefficient of thermal expansion at 20 °C | Scale max length |

Narrow stainless steel partial arc tape  | RKLF-S | ±15 µm/m | 40 µm | 10.1 ±0.2 μm/m/°C | Up to 10 m (> 10 m on request) |

Rotary

Scale type | Scale name | Graduation accuracy | Scale pitch | Coefficient of thermal expansion at 20 °C | Disc outer diameter |

Glass disc

| RCDM | ±0.5 µm (disc ø up to 100 mm) ±0.7 µm (disc ø over 100 mm) | 20 µm/40 µm | ~8 µm/m/°C | 17 mm to 108 mm |

CENTRUM™ stainless steel disc

| CSF40 | ±0.5 µm | 40 µm | 15.5 ±0.5 µm/m/°C | Fixing options: Bolts: 38.4 mm to 120 mm Clamp: 31 mm to 120 mm For other sizes, contact Renishaw |

Optional Advanced Diagnostic Tools

The Advanced Diagnostic Tools assist in system set-up and planned maintenance to help minimise unscheduled machine downtime.

The ADTpro-100 is a handheld, standalone encoder diagnostic tool featuring an integral colour touch screen. The ADTpro-100:

- Requires no computer or additional set-up equipment to display comprehensive real-time encoder information.

- Is easy and intuitive to use with plug-and-play functionality to aid system set-up and calibration.

- Interfaces with the optional ADT View computer software, which allows encoder data to be saved as a record of the system setup and performance. ADT View can also be used to update the ADTpro-100 firmware

The ADTi-100, in conjunction with the intuitive ADT View computer software:

- Provides comprehensive real-time encoder data feedback to aid more challenging installations and diagnostics.

- Assists system set-up, calibration and signal optimisation along the entire axis.

- Allows data, such as signal strength vs position along the axis, to be saved as a record of the system setup and performance.

Both the ADTpro-100 and ADTi-100 are ideal for aiding system optimisation and diagnostics, particularly for installations when the readhead LED is not visible. They can be used standalone or in-line, connected between the readhead and the controller as part of the control loop.